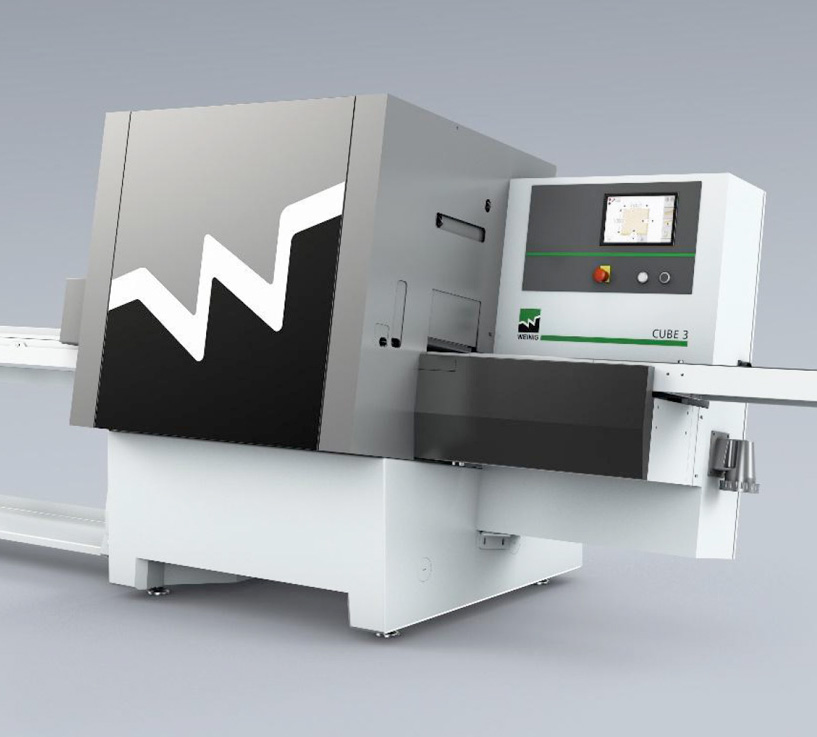

Sanding individual Faces – Calibrating solid, doors or base board, finish sanding of solid timber frames and veneers, denibbing lacquer in one or multiple passes.

- Sanding size: Extremely large sanding size considering the overall machine dimension.

- Touch screen: Effortless touchscreen control for all adjustments.

- Enormatic: Fully automatic quick setting and feed release.

- Constant Pass Line: Top moving heads, the raising and lowering of the sanding units enable thicknessing of the product. With infeed and outfeed tables if required at a constant level.

- Health & Safety: Superb health and safety features.

- Single Button Startup: Single-button cascade start-up and highly efficient motors.

- Sanding weight: Heavy board can be sanded due to the fixed table.

- Heavy duty: Heavy-duty steel framed body

Adjustment: Electric compensation of the abrasive belt grain thickness.

2 or 3 units / 1350mm wide x 200mm max deep. / 3-15m per minute feed speed / 1350x2000mm sanding belt dimension / The superb Enormatic setting system / Touch screen technology assists the operator / 18.5kw single motor / electronic compensation for the belt grit..